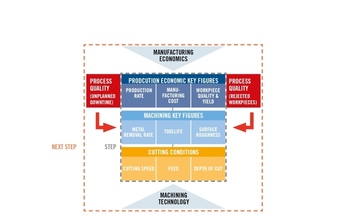

Total image of all elements and how they relate and interact, in a manufacturing plant (NEXT STEP model and concept).

A third group of activities in the machining system are those that are unneeded. These activities neither create value nor enable creation of value, but rather consume resources with no benefit. They are purely occasions of waste. Problem solving is an example of unneeded activity. If a process is properly designed and controlled in the first place, there will be no problems and no time wasted solving them.

Figure 5 - Schematic picture of a machining workshop and all the elements related to it.

Conclusion

For much of the past, unneeded activities were accepted as part of the manufacturing process and not recognized as significant disruptors of the achievement of balanced production economics. Presently, attention is turning to the elimination or minimisation of unneeded activity. The focus of productivity or capacity planning is on eliminating unneeded activities, minimizing value enabling activities and optimising value adding activities. (See Figure 6)

Figure 6 - Overview of value adding adding activities (orange), value enabling activities (blue) and waste activities (red). The people factor (grey) is the key factor to reach optimum achievement of manufacturing top performance.

When waste is eliminated, theoretical production economics become practical production economics. At that point, progress in production economics can be applied directly to company success. However, in the effort to eliminate every occasion of waste, caution is necessary. It is important to quantify the return on investment of waste reduction activities. Totally eliminating a certain incidence of waste might involve an investment that is so large that from an economic perspective it may be better to accept the waste, or a portion of it, and live with it. Such decisions are made following appropriate quantitative analysis as well as intra-company discussions regarding how the decisions will affect company goals and philosophies.

(Continued on next page)