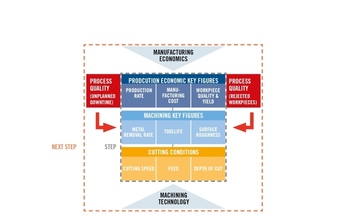

Total image of all elements and how they relate and interact, in a manufacturing plant (NEXT STEP model and concept).

Seco Consultancy Services

As manufacturing products become more sophisticated, users need increasing amounts of application assistance to realise maximum benefits from the new technologies. In machining, the initial level of assistance is guidance in the selection of the right tool for a certain operation. After a tool is selected, further information facilitates choice of optimal cutting conditions, use of coolant and other considerations. Then, if a tool fails to function as expected in that operation, the tool supplier can provide troubleshooting help. These three modes of assistance make up traditional tooling services.

When tooling service expands from a single application to cover a process in which a workpiece is subject to multiple operations on one or more machines, end users require guidance in arranging the sequence of operations, workpiece manipulation and other factors to maximise efficiency and productivity. That level of assistance can be called engineering services.

More and more frequently, manufacturers are seeking direction in improving functions, output and cost control for an entire shop or organization. In these cases, some independent consulting companies perform what they describe as management or manufacturing consulting. However, to do a true evaluation of a manufacturing organization, it is essential to fully understand the business's core operations.

Applying its long and extensive understanding of machining processes and tooling, Seco has been providing traditional tooling services, engineering services and to some extend bigger-picture consulting for decades. Those services were offered on a contingent or situation-specific basis, but in 2016, Seco formed its Consulting Services to provide its customers with a more streamlined and responsive array of manufacturing services.

(Continued on next page)