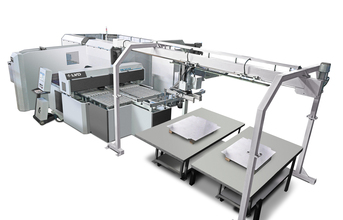

LVD Company nv has added panel benders to its portfolio of flexible solutions for sheet metal processing. The new product line offers a range of panel bending equipment, including high speed panel bending systems. LVD will launch the new line at Blechexpo with the unveiling of the PB 21/12 automatic panel bending machine.

Panel bending technology can process large and complex geometries, quickly and efficiently with high productivity in medium to high volumes. For certain applications, panel bending is faster and more efficient than traditional die bending.

LVD panel benders are cost-effective machines that can be customised to expand capacity and performance. Their servo-driven design requires minimal service and is nearly maintenance-free. A universal set of folding blades permits processing of a wide range of profiles and bends. LVD panel benders boast an output capacity two to three times that of comparable systems.

Panel bending technology is ideal for producing large electrical cabinets, panels and cabinet components, shelving, clean rooms, steel furniture, architectural building panels, photo-voltaic components, trailer side panels, lighting and industrial equipment panels featuring complex geometries with radius bends, short side lengths, and narrow profiles.

LVD will initially offer three models of panel benders: PB 21/12, PB 25/12, and PB 32/12 to handle panel sizes up to 3200 mm x 1250 mm.