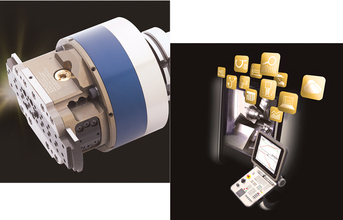

Facing head with direct position measuring system

Mechatronic tools such as precision adjustment heads, facing heads and the KomTronic U-axis systems, available in several variants, are one of the specialities of the KOMET GROUP. A patented direct encoder has been available as an optional extra for U-axes and the purely mechanical KomDrive facing heads for two years. In order to enable encoding to take place directly on the slider, the encoder also takes disturbance variables of mechanical elements into account, such as the drive element tolerances, the temperature range and wear. The control system can respond to the measurement data immediately, providing accuracy to +/- 3 μm and thereby enabling outstanding machining quality to be achieved.

Tool and process expertise from a single source

KOMET BRINKHAUS GmbH has been part of the KOMET GROUP for more than three years. As a result of the interaction between tool experts and process monitoring specialists, it has been possible to further develop the ToolScope process monitoring system into an integrated assistance system in terms of Industry 4.0. It monitors the internal signals from the machine, detects events such as tool changes or machine stoppage and is able to calculate parameters and deduce trends. At AMB 2016, KOMET is demonstrating how easy ToolScope is to use: Customers can select the solutions they require from the broad range of applications - from tool monitoring to an automatic tool change log through to adaptive feed control - and license them individually. Operation of the system has also become more flexible: Users can now view and operate their custom assistance system on mobile terminals such as tablets and smartphones.

For more details, contact

KOMET Precision tools India Pvt ltd

Email: info.in@kometgroup.com, Web: www.kometgroup.com

END