Machining tools are becoming increasingly efficient. This is what the KOMET GROUP is demonstrating at AMB 2016, where the precision tools manufacturer is presenting numerous innovations under the trade fair slogan "TOTAL PRODUCTIVITY SOLUTIONS". Highlights include the growing range of milling tools that can also be used in generative manufacturing processes, as well as a completely new indexable insert reaming tool and unique expansions of the KOMET KUB Pentron drill. Other attractions include the numerous innovations in mechatronic tools and ultrahard cutting tool materials as well as the KOMET ToolScope assistance system, which bridges the gap from machining to Industry 4.0.

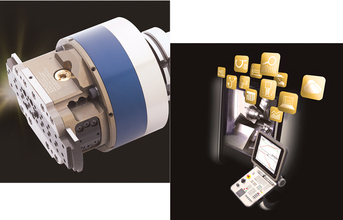

Alongside the KOMET solid carbide milling cutters for all requirements in the diameter range of 3.0-25.0 mm, the KOMET indexable insert milling cutters have primarily been subject to further improvements.

The cutter holders in the redesigned KOMET PCD milling cutters are manufactured using the generative process of laser melting, which means that these new tools can offer feed rates up to 50 percent higher than before. 3D printing enables up to twice as many cutting edges to be created-regardless of diameter. KOMET is also utilising the structural flexibility provided by the additive manufacturing process to create a perfect design for the course of the coolant channels inside these milling cutters. Curved channel routes now reduce pressure loss in the coolant and are positioned precisely in such a way that every cutting edge is supplied with coolant from a separate channel.

Aside from the new production process, KOMET is also expanding its milling range with new designs, such as the KOMET hi.aeQ 45° face-milling cutter, which has a feed rate of up to 40 percent higher than a shoulder milling cutter. Moreover, the company is also launching new PCD milling and thread milling tools to standard versions that can be particularly productive when used in applications involving lightweight construction materials.

(Continued on next month)