Coperion K-Tron announces the addition of powder-feeding alternatives to its original ProRate™ PLUS feeder line. A ProRate PLUS-MT twin screw feeder will be added to the product line by the end of April 2023. When combined with the recently launched ProFlow™ bulk solids activator, it is an effective solution for feeding powder additives in plastic applications. This addition is the result of the company's 100 years of feeding knowledge and is intended to provide a cost-effective option for feeding powder additives in plastic applications. The gravimetric feeder line is an economical solution and offers a quick return on investment due to its good cost-performance ratio and fast delivery.

A new twin screw feeder is ideal for powder additives

With its horizontal agitator, this expansion is ideal for more difficult-to-handle powder additives, including talc, calcium carbonate, and carbon black. The twin screw technology decreases pulsations, while the steep shape of its hopper walls enables reliable feeding of poorly moving bulk solids. If material bridging or ratholes persist, ProFlow bulk solids activators are fitted to aid the material flow.

Controlled vibrations improve feeder performance

To complement the ProRate PLUS-MT twin screw feeder, the company has introduced the ProFlow™ bulk solids activator. The activator is available for all four models of the ProRate PLUS feeder line and is designed to keep bulk materials moving with minimal energy consumption and maximum product flow. The ProFlow bulk solid activator operates at an optimized frequency and amplitude to ensure efficient product flow. The solution has no worn parts and requires no additional cleaning efforts as it is mounted outside the product contact area.

The inclusion of an electromagnetic vibrating device that operates at an optimised frequency ensures minimal energy consumption and maximum product flow. Tests have shown that ProFlow is an ideal solution for a variety of bulk materials.

Clever design features for ease of use

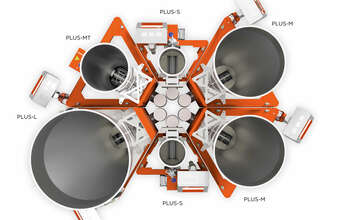

The ProRate PLUS feeder line is highly standardized, with a variety of design features to optimize performance and ease of use. It features a space-saving trapezoidal shape that allows up to six feeders to be easily grouped around an extruder inlet within a 1.5-meter radius. The four feeder models cover a wide range of throughputs and are capable of handling feed rates from 3.3 to 4800 dm3/h, depending on the material. Furthermore, they are equipped with P-SFT load cells, featuring reliable Smart Force Transducer single-wire weighing technology, and each feeder comes with its own pre-wired and pre-tested ProRate PLUS PCM control module.

The ProRate PLUS feeders and ProFlow bulk solids activator are suitable for use in hazardous locations rated NEC Class II, Div. 2, Group F & G, and ATEX 3D/3D (outside/inside). Preconfigured pneumatic refill solutions are available for each feeder size, ensuring a continuous supply of materials.