Renishaw plans to showcase its latest scanning solutions for machine tools at EMO Hannover 2019. On-machine scanning will be one of many smart factory process control solutions demonstrated by Renishaw, which are proven to help machine shops across many industries transform their production capabilities.

Reducing cycle time, improving productivity and eliminating scrap are consistent driving forces for manufacturers across numerous industrial applications. Whilst onmachine touch-trigger probing is a widely accepted solution to address these challenges, its use can often be restricted in applications where minimising cycle time and maximising data density are key requirements.

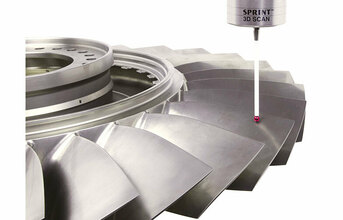

On-machine scanning solutions such as Renishaw's OSP60 probe with SPRINT™ technology can address these limitations, making probing viable in applications that were previously impractical. Unlike other on-machine scanning systems which only output data in 1D, the patented 3D sensor technology in the OSP60 probe can output 1000, true 3D (X, Y, Z position) data points per second, enabling true form analysis and defect detection at unprecedented feedrates.

The OSP60 probe, combined with a host of powerful software tools from Renishaw, provides 'real surface modelling' which can be used in a variety of different applications and downstream operations to dramatically improve production processes. Benefitting from the high density data captured by the 3D scanning system, applications include on-machine health checks prior to machining, part set-up and feature measurement, surface condition monitoring of flat sealing faces, 3D surface measurement for the manufacture of complex parts such as blades, and the adaptive machining of parts, such as castings which have variable form.

Machine tool builders and end users alike are increasingly adopting on-machine scanning across numerous industries to benefit from the enhanced capability it provides, strengthening their manufacturing processes and gaining operational advantages.

Source: Renishaw

END