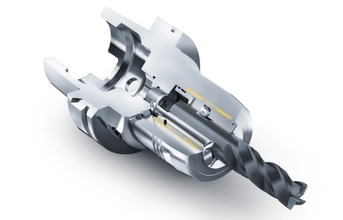

SCHUNK TENDO AVIATION combines the advantages of the SCHUNK TENDO hydraulic expansion technology and of a Weldon chuck. An integrated anti pull-out locking mechanism avoids slipping out of the tool and damages at the workpiece. Moreover, the cutting data can be partly increased.

SCHUNK, the competence leader for clamping technology and gripping systems extends its program for high performance hydraulic expansion toolholders with the TENDO AVIATION.

After the introduction of the powerful SCHUNK TENDO-E compact universal toolholder in 2010, SCHUNK continues this unique story of success, by focusing on demanding precision applications, which particularly occur in the aerospace industry. Safety mechanisms such as anti pull-out locking mechanisms are partly mandatory in this industry.

Combining advantages of two clamping technologies

TENDO AVIATION combines the strengths of hydraulic expansion technology with the ones of Weldon toolholders: it convinces with a permanently high run-out accuracy, a balancing grade of G 2.5 at 25,000 min-1, perfect vibration damping, and a fast tool change using an Allen key.

For the use of Weldon shanks, an integrated anti pull-out locking mechanism ensures an orientation of the tools and form-fit clamping, which prevents slipping out of the tool, and even tight shape and positional tolerances can be maintained. Moreover, the potentials of tool and machine can be fully used. TENDO AVIATION allows maximum torque transmission at a consistently high precision and process reliability. Compared with conventional Weldon mountings, and heat shrinking toolholders, where the run-out accuracy decreases with time, it offers tremendous advantages. The typical synergy of run-out accuracy and vibration damping of the TENDO hydraulic toolholders prevents the cutting edge from wear, extends the tool live, and ensures brilliant surfaces. Moreover, the uniform load profile ensures an extension of the service life of spindle and spindle bearing.

Particularly economical

As all the SCHUNK hydraulic expansion toolholders, the TENDO AVIATION does not need any additional and partly expensive peripheral equipment. This price-attractive high-end

toolholder is exclusively manufactured at the SCHUNK headquarters in Lauffen, Germany, and as a first step they are available for the interfaces HSK-A63 (ø 8mm, 10 mm, 12 mm, and 16mm; and HSK-A100 (ø 16 mm, 20 mm, and 25 mm). The clamping diameter can be reduced by using intermediate sleeves. In contrast to the ER collet cucks, or the heat shrinking mountings, TENDO AVIATION is resistant against dirt, and requires low-maintenance. In order to increase the service live of precision mountings, and to maintain maximum process stability during sensible processes, the precision mounting can be inspected, and if necessary optimized during a performance check of the SCHUNK Service.

Contact: Satish Sadasivan; Schunk Intec India Private Limited; Ph.: 080-40538999; Fax: 080-40538998; Email: info@in.schunk.com; Web: www.in.schunk.com

New flagship for demanding precision machining

Image:

Caption: SCHUNK TENDO AVIATION combines the advantages of the SCHUNK TENDO hydraulic expansion technology and of a Weldon chuck. An integrated anti pull-out locking mechanism avoids slipping out of the tool and damages at the workpiece. Moreover, the cutting data can be partly increased.

SCHUNK, the competence leader for clamping technology and gripping systems extends its program for high performance hydraulic expansion toolholders with the TENDO AVIATION. After the introduction of the powerful SCHUNK TENDO-E compact universal toolholder in 2010, SCHUNK continues this unique story of success, by focusing on demanding precision applications, which particularly occur in the aerospace industry. Safety mechanisms such as anti pull-out locking mechanisms are partly mandatory in this industry.

Combining advantages of two clamping technologies

TENDO AVIATION combines the strengths of hydraulic expansion technology with the ones of Weldon toolholders: it convinces with a permanently high run-out accuracy, a balancing grade of G 2.5 at 25,000 min-1, perfect vibration damping, and a fast tool change using an Allen key. For the use of Weldon shanks, an integrated anti pull-out locking mechanism ensures an orientation of the tools and form-fit clamping, which prevents slipping out of the tool, and even tight shape and positional tolerances can be maintained. Moreover, the potentials of tool and machine can be fully used. TENDO AVIATION allows maximum torque transmission at a consistently high precision and process reliability. Compared with conventional Weldon mountings, and heat shrinking toolholders, where the run-out accuracy decreases with time, it offers tremendous advantages. The typical synergy of run-out accuracy and vibration damping of the TENDO hydraulic toolholders prevents the cutting edge from wear, extends the tool live, and ensures brilliant surfaces. Moreover, the uniform load profile ensures an extension of the service life of spindle and spindle bearing.

Particularly economical

As all the SCHUNK hydraulic expansion toolholders, the TENDO AVIATION does not need any additional and partly expensive peripheral equipment. This price-attractive high-end

toolholder is exclusively manufactured at the SCHUNK headquarters in Lauffen, Germany, and as a first step they are available for the interfaces HSK-A63 (ø 8mm, 10 mm, 12 mm, and 16mm; and HSK-A100 (ø 16 mm, 20 mm, and 25 mm). The clamping diameter can be reduced by using intermediate sleeves. In contrast to the ER collet cucks, or the heat shrinking mountings, TENDO AVIATION is resistant against dirt, and requires low-maintenance. In order to increase the service live of precision mountings, and to maintain maximum process stability during sensible processes, the precision mounting can be inspected, and if necessary optimized during a performance check of the SCHUNK Service.