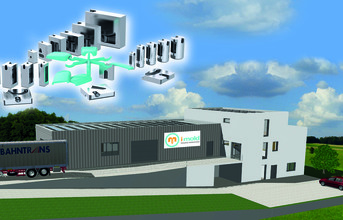

In 2022, i-mold emerged as an independent supplier to injection moulding tool manufacturers. Now, the company has taken a giant leap forward with its brand-new facility in Michelstadt, inaugurated on August 1st.

Spanning an impressive 760m², this state-of-the-art headquarters provides CEO Andy Walter and his team ample space for development, production, marketing, and logistics.

For over two decades, i-mold has been synonymous with customer-focused excellence, particularly in creating highly wear-resistant, easy-flow tunnel gate inserts. These inserts have proven to be a game-changer in various applications, offering seamless injection moulded parts with superior functionality, especially for visible components.

Expanding its offerings, i-mold includes hot runner systems from Heatlock, sprue adjusters for precise melt flow control, and the Nanomold mould coating, ensuring immaculate mould surfaces and smooth demoulding processes. Customers can access this comprehensive portfolio directly from i-mold or through its global network of distributors.

CEO Walter shares, "Our tunnel gate inserts, available in diverse geometries and dimensions, have already made their mark in 33 countries across industries. With a current demand of 15,000 units per year and growing, our new headquarters empowers us to innovate further and meet our customers' needs promptly and comprehensively."