- ABB India introduces AI-Powered Startup Challenge

- Tech Data and NVIDIA extends partnership with new distribution agreement

- JCBL Group ties up with Slovakia to manufacture next-gen combat vehicles

- Turkon Line launches India services in strategic tie-up with Abrao Group

- Powering growth through innovation, integration, and expansion

Enhancing general-purpose machine shops' performance

There are numerous small shops across the world, which deal with no particular industry or technology. Haas machines help such shops to carry out their jobs efficiently.

Cluster development for business excellence

Clusters have the philosophy of ‘getting together, learning together, achieving together’.

Quality and reliability take precedence at Subspec

With Haas CNC machining capability in-house, Subspec Srl is able to control cost, new product development and, critically, part quality.

Metal packaging production at top speed manufactures around 180-200 aerosol cans per minute

A case study on Alumatic Cans Pvt Ltd

New machine for old designs

Haas CNC VF-5/40XT– a 40-taper vertical machining centre with an extra-long, 60 inch (1524 mm) table helps in machining of cylinder heads for the V12 Merlin aero engine.

Solid stamp of trust and reliability

When a well-known locking solutions and systems manufacturer decided to go for CNC machines, it categorised the supplier on the basis of power required to run the machine, operational...

Ensuring precision

A tier one auto component supplier uses machine tool probes for precision metrology in the manufacturing of forged wheel and car chassis to meet quality requirements for the European...

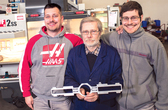

The Model Maker, His Wife, and His Muse

If you spend most of your waking hours in a business running CNC machine tools, life is sweeter if the machines are easy to use and you like them – a lot.

Adding value 'smoothly'

Yatendra Kumar, Business Head, MotulTech India, shares a couple of industry examples demonstrating the advantage of using high performance lubricants

From five hours to 50 minutes

Walter tools at work in the toughest of machining conditions