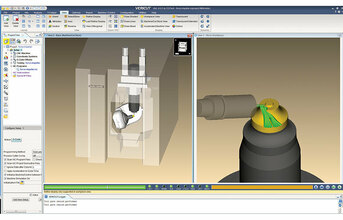

CGTech is powering into IMTEX 2019 with its latest physics-based feed rate Optimisation module, VERICUT Force. The VERICUT remains at the heart of the CNC manufacturing process for many of the leading automotive & motorsport engineering businesses. The latest release, VERICUT 8.2, introduces a new optimisation module - Force Turning. Force is a physics-based NC program optimisation module that analyses & optimises cutting conditions to achieve ideal chip thicknesses, while managing the cutting forces & spindle power required. The latest module, Force Turning, optimise turning and mill-turn operations, when combined with Force Milling. Force Turning makes it easy for anyone to create NC programs for optimal cutting of inside/outside diameters, shoulders, as well as in corners & tight spaces - without the worry of encountering excessive cutting forces or high spindle power demands. Force provides NC programmers with detailed information about the cutting process that they never had before. NC programmers quickly and easily identify problems and unsafe cutting conditions lurking in their NC programs. With a single click, users can review problem-causing cuts, which if left uncorrected, could cause chatter, break the tool and damage the part or machine. Force optimisation automatically corrects these issues, like excessive cutting forces, metal removal rates, power, torque & tool deflection while simultaneously correcting underutilised cutting conditions by raising them to optimal performance levels. CGTech also offers Additive Manufacturing capabilities as well as VERICUT Composites application for programming and simulation of Automated Fiber-Placement & Tape-Laying Machines. See the entire VERICUT suite on (AMT Pavilion) at IMTEX 2019.

END