The Y-axis option has broadened the possibilities to use rotating tools in multi-task machines and turning centres. Now this capability has inspired a great innovation in one of the original missions of these machine tool types: Y-axis parting. Implementing this new tool and method brings significant machining improvements in potentially any parting operation.

Adding rotating tools to turning centres means you can combine several set-ups in a single machine for a more streamlined and productive machining process. To accomplish this, turn-mill machines were introduced in the 1990s. The initial idea was to enable driving a milling cutter, drill or threading tap on one or more tool positions in the turret to eliminate limitations of polar interpolation and other related programming difficulties. To improve reach, an extra set of ways was added to move the rotating tool across the spindle face. This was accomplished by mounting the tools on revolver sides or on its face, by installing the Y-axis ways on a slanted bed or by using an independent milling head. Both machine tool makers and manufacturers soon recognized the benefits of integrating both milling and turning operations. Today, the Y-axis option has become a standard feature in most multi-task machines and optional in many new turning centres.

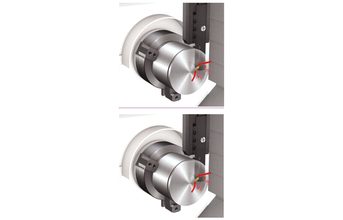

As a potential tool breakage risks leading to costly machine downtime or scrapped components, parting off is a stage of the machining process where manufacturers don't compromise on security. To meet the high demands put on these type of tools, the system CoroCut® QD was developed by Sandvik Coromant in 2013. While considering how to improve this high-performing system even further, the tool developers started looking at these modern machines with Y-axis capacity. This resulted in an innovation that involved more than just the tool design but also a completely new method: Y-axis parting.

(Continued on next page)