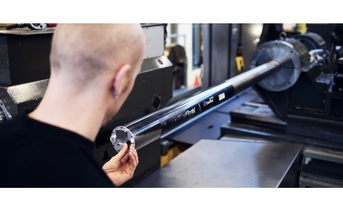

The SilentTools+ boring bars are part of the CoroPlus platform, comprising connected tools and software. Dan Östling, another PhD engineer on the Trondheim team, has been driving the development of the sensor and signal technology - technology that opens up a world of new opportunities for customers from pre-machining all the way to post-machining. R&D engineer Mathias Tjomsland demonstrates the interface while one of the operators attaches a long, heavy boring bar to the machine. The icon for centre height displays 0.0°.

"Wow, you got it exactly right on the first try," Tjomsland tells the operator.

Without connectivity, operators spend a lot of time measuring, listening, feeling and watching before, during and after machining. Components of the size that this bar can machine are extremely expensive, which means that process stability is key. During a visit to several aerospace manufacturers in Canada, the R&D team realized another challenge - lack of visibility.

"When turning inside long components, it's extremely difficult to know what is going on," Tjomsland says. "In modern machining centres, you may not even know if the insert is actually in cut, as they are very sound-isolated. Every minute the machine is cutting air is very expensive."

(Continued on next page)