Everything the Silent Tools R&D team in Norway does is based on customer demands, add curiosity and a desire to learn to this and you'll have the recipe why the team is so good at innovation.

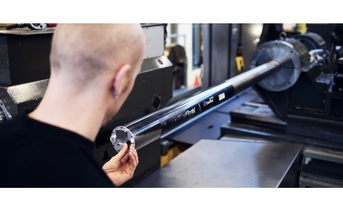

The view is marvellous: black wintry water cutting through snow-covered mountains surrounding a fjord. This is Trondheim, Norway, and it's where you'll find the brains behind the next generation of connected Silent Tools™+ boring bars.

Industry 4.0 and the constant demand for new innovations can be stressful for companies, but Sandvik Coromant in Norway has created an environment for bright ideas to flourish. It's no coincidence that competitors are still struggling to produce vibration-free boring bar lengths above 10 times the hole diameter while the team in Trondheim is testing bars that can handle double that, now with connectivity and software that save valuable time and money for the customers. What's the secret?

"It's a combination of many things," says R&D manager Anders Digernes. "We have the full value chain from ideas to complete manufactured products under the same roof, which gives us access to a lot of different competences. Our flat organizational structure makes us very flexible and agile in our response to new opportunities, often identified through R&D's direct contact with customers."

Tormod Jensen, a PhD engineer on the R&D team and one of the brains behind several patents of the Silent Tools dampening system and sensor technology, points to another reason. "We are part of the large Smart Tools project founded by the Research Council of Norway, and this has been a key factor in our success," he says.

(Continued on next page)