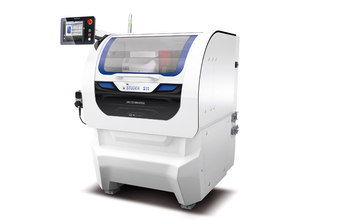

The S11 gives you great performance in a minimum of space. Image courtesy: Studer

Extended scope of application

The conversion to the new control in the S11 provides even more advantages for users of the small, powerful production cylindrical grinding machine. Up to now, they were only able to work at grinding wheel speeds of 50 m/s (in exceptional cases max. 80 m/s).

Today thanks to the combination of a Fanuc Control and StuderGRIND HSG machining is possible with CBN grinding wheels and grinding speeds of up to 140 m/s. A new high-speed spindle has been designed especially for the S11. The S11 achieves an extremely high abrasion performance in a minimum amount of space.

Similarly, the S11 now also enables typical C-axis applications such as thread and form grinding. This is made possible by a new version of the workhead with C-axis function in combination with the software modules StuderThread or StuderForm.

The new and reprofiling of grinding wheels thanks to an optimized clearing strategy with StuderDress and machining of longitudinal contours with StuderContour extends the scope of application of the S11.

Above and beyond this, the new S11 also features the SBS Dynamic Balance System. This combined system for contact detection by means of vibration measuring and for semi and fully automatic balancing of the grinding wheels, reduces downtime thanks to less air grinding. It also enables the process to be monitored, for example observation of grinding level noise.

Optimised accessibility and automation casing

Studer offers the S11 in two different casing designs: The existing version is specially designed for manual loading or to be combined with small handling systems.

The new casing is optimized for vertical loading with a top hatch. It is perfect for inter-linked production in which the machines are loaded and unloaded via portal cranes. Both designs stand out with their excellent accessibility and ergonomic features.

* The programming software StuderWIN focus with its standard grinding cycles is perfect for a the most different grinding operations and includes optimized input masks in which the user simply has to enter the application specific grinding parameters.

** The offline programming software StuderGRIND is made up of a variety of modules. The following modules are available on request for the S11:

StuderDress for optimised clearing strategy, for profiling grinding wheels.

StuderThread for thread grinding.

StuderForm for form grinding.

StuderContour for grinding longitudinal contours.

StuderGeoImport for convenient use of workpiece geometry straight from a DXF file.

For more details: Contact Belinda Juhasz at belinda.juhasz@studer.com or visit www.studer.com