Sealing gaps with acrylic impregnation

Acrylic impregnation products such as Loctite IS 5100 provide a sealing solution for electrical and electronic components. Microscopic voids are inherent in many electronic assemblies that combine metal and plastics elements. Over time in the field, these voids can cause product failures, so it is important that they are filled before the parts are put into vehicles. Henkel offers an impregnation service, either on-site or at its own service centers, for permanently sealing parts such as sensors, connectors, coils and electronic housings. Once impregnated, these components are protected from moisture, solvents, fluxes and other corrosive agents.

The impregnation process involves putting parts into a vacuum chamber, which is then filled with the acrylic resin. Once this has filled all the gaps in the parts, excess resin is removed by a centrifuge and parts are then thoroughly washed and rinsed before the remaining resin is allowed to cure. All parts go through a leak test to guarantee that the process has sealed the parts.

Impregnation is a fast, high quality, cost-effective sealing solution that can be used on existing parts without any need for design changes. Once treated, parts have the same dimensions and surface aspect as untreated parts, but their durability and long-term reliability is considerably improved. The specially developed acrylic resin protects against moisture, chemicals and dust, and remains flexible, retaining its sealing properties, throughout multiple thermal cycles. The process is unique to Henkel. Since it is offered as a service, customers do not need to invest in any capital equipment.

Potting with thermally conductive resins

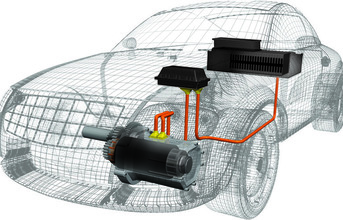

Henkel's thermally conductive potting materials are intended for electric automobile propulsion components that require support in dissipating generated heat.

Today's compact high-performance electric propulsion components have a high power density. This inevitably leads to the generation of heat, which must be discharged to the cooling system on the outside if reliability is not to suffer. Henkel offers a variety of thermally conductive and electrically insulating potting materials that meet the technical and processing requirements of this application.