Low-pressure hot-melt polyamide encapsulation

In the low-pressure hot-melt moulding technique, resin is injected around components fixed in a closed mold. The hot-melt serves as an encapsulant and also as a housing, so there is no need for a separate shell to protect the components. Once the hot-melt material has cooled and solidified, the components are ready for further processing.

Resins for hot-melt moulding are single-component polyamide systems that can be used in simple and clean production processes. These processes take up little floor space, they are fast and energy-efficient.

Henkel Technomelt hot-melt molding materials provide high humidity resistance, temperature resistance up to 150°C, and impact resistance down to -50°C. This makes them superior to many other polyamide hot-melts, which normally can be used in environments of up to only 120°C and are more prone to hydrolysis.

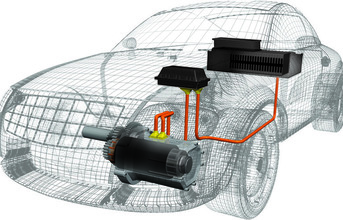

The new materials from Henkel are the result of experience in hot-melt molding for the automotive industry that dates back over 25 years. They provide new opportunities for higher temperature applications in humid environments, such as sensors in door handles, rear view cameras, batteries or tire pressure monitoring systems, or for sealing aluminium cables.

(Continued on next page)