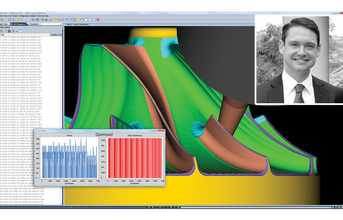

VERICUT Force is a physics-based optimisation method that determines the maximum reliable feed rate for a given cutting condition based on the following four factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate.

It calculates ideal feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting edge geometry, and VERICUT cut-by-cut contact conditions. Force interpolates cutting conditions using a proprietary set of materials coefficients to account for the strength of material and the effects of friction and temperature.

The materials data is created from actual machining tests and does not rely on extrapolating from finite element analysis results. The unique cutting coefficients used by Force result in the most accurate cutting force calculations available today. Turning and drilling optimisation capabilities are coming soon.

Force excels in difficult to machine materials, and especially complex multi-axis cuts such as 5-axis flank milling. Once the material is characterised, it can be applied to a broad range of cutters and machines in future NC machining operations. It's easy to set-up and can also predict tool wear.

The initial users of this technology are already seeing productivity improvements of up to 50 percent. Other benefits include reduced development time, shorter cycle times, less process variation, longer machine life and improved part quality. It can also prevent tool breakage due to deflection.

What does VERICUT support more efficiently - ‘low volume, high variety production' or ‘high volume, mass production'?

VERICUT enables you to eliminate the process of manually proving-out NC programs. It reduces scrap loss and rework. The program also optimises NC programs in order to both save time and produce higher quality surface finish. VERICUT simulates all types of CNC machine tools, including those from leading manufacturers.

END