How does the VERICUT Drilling and Fastening (VDAF) software help the aerospace industry?

Airframe drilling and fastening has a different set of requirements for process simulation. The CNC machine drills holes through an assembly of airframe components such as the outer skin and inner frames, connecting stringers and other structural hardware. It then installs a fastener through the hole and ties the components together.

A given assembly operation can have more than 10,000 drill and fasten operations in a single NC program. While it may seem obvious to assume the drilling operation is a machining operation, the purpose of the simulation is not to validate the material removal by the drill. It is instead important to validate that the drill passed through the proper assembly components and drilled the correct hole in the correct location and at the correct size. The process simulation requirements for automated airframe assembly are very different from machining, even though both may do drilling operations with a CNC machine.

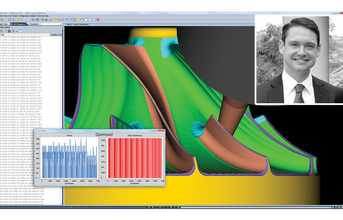

VERICUT Drilling and Fastening (VDAF) is software for simulating and programming auto-drilling and fastening machines. These machines are used to assemble large aero-structures and it is essential to avoid programming errors and collisions at such a late stage in the aircraft manufacturing process. VERICUT allows the user to program drilling and fastener assembly operations in a virtual machine tool environment and provides simulation to check for a variety of potentially disastrous error conditions. VDAF interfaces to leading CAD/CAM/PLM systems such as Dassault Systemes CATIA and Siemens NX, and is independent of the assembly machine manufacturer.

(Continued on the next page)