High cutting speed is a natural attribute of high speed machining. Understandably, a tool should be also precise; it is required not only by machining accuracy but also by the mechanics of a fast-rotating body. However, in last few years the issue of tool accuracy has become an additional point to consider.

The metalworking industry adopted high speed machining (HSM) in 1990s. This method was engrained in varied industrial branches & caused changes in technology & machine tool engineering. Accurate machining means maintaining repeatable strict tolerances during cutting operations. The level of such ‘strictness' depends on the machining method, E.g.: milling, turning, or drilling, & the type of operation: rough, semi-finish or finish. Technological advances, especially in producing workpieces that are preformed half-finished products, place special emphasis on accurate high speed machining. Precise casting, metal injection molding & 3D printing ensure that the production of workpieces is very close to the final shape of a part. As a result, the need to remove a high volume of material by means of rough cutting decreases. As for manufacturing aluminium components, HSM has simply become a daily reality.

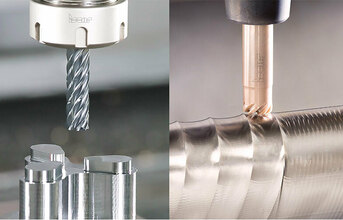

Machining operations with low stocks per pass have distinct advantages like lower power consumption, less heat generation, & better surface finish. Accurate HSM, which features low stock removal, is a logical extension of producing workpieces by precise modern methods. Usually, HSM relates to cutting by rotating tools - mainly milling cutters. In many cases, when a part featuring complex profiles & slots is produced from a solid material, HSM provides productive low-loaded roughing by trochoidal milling. As per this technique, a rapidly rotating milling cutter moves along a complicated trajectory & slices thin but wide layers of the material. This results in pre-shaping the part very close to a final form. The remaining small allowance is removed in the next stage: high speed finish milling. Producing blisks (bladed discs) & impellers is a typical example of the mentioned process that may be defined by the rather oxymoronic term: ‘accurate roughing'.

Successful HSM relies on a key element chain comprising a machine tool, a machining strategy, proper toolholding, & a cutting tool. The lowpower multi-axis machine tools designed especially for

HSM feature high-torque characteristics, high-velocity drives, effective controllers & intelligent software. Today, metalworking has in its arsenal highly reliable tool holders designed for secure tool mounting in an expanded range of rotational speeds. Under such conditions the cutting tool - the element that directly contacts a machined part during a cutting operation - can be a limiting factor in maximizing the potential of advanced machine tools. Time has not radically changed principal tool requirements: it is expected to be more durable & more efficient when cutting at considerably increased cutting speeds and feed rates. Lowering machining allowances leads to additional tightening tool accuracy parameters. An ideal product is a precise & high-balanced tool that ensures high performance in combination with excellent tool life when cutting at high rotational speeds. ISCAR, staying true to its motto ‘Where innovation never stops!', has developed a range of solutions that give new momentum to HSM concepts, & many proposed designs relate to the field of solid carbide tools.

More flutes, less vibrations

Multi-flute solid carbide endmills from ISCAR's "CHATTERFREE" line were developed especially for vibration-free high speed machining operations. Their design features a varying helix angle, variable tooth pitch & a specially shaped chip gullet, intended for applications like semi-finish & finish high speed milling, as well as roughing by trochoidal technique. The CHATTERFREE range comprises several endmill families for different applications. 7 flute endmills, produced from an ultra-fine carbide grade, are designed for machining hard materials & finish operations. Generalpurpose multi-flute endmills incorporate an interesting concept, according to which the number of teeth is equal to a nominal diameter in mm. 7- and 9 flute endmills were designed originally for trochoidal milling complex parts from titanium & today they form the Ti-TURBO family - this name reflects a real ‘turbo' metal removal rate when milling titanium The latest step of the line development integrates chip-splitting grooves in the endmill design. The new geometry has an unusual appearance because HSM forms thin chips that do not appear to need an additional chip-splitting action. However, the grooves increase vibration resistance & reduce cutting forces, significantly improving trochoidal milling & machining performance at high overhangs. In trochoidal milling, the produced chips are thin but wide. Splitting the chips into narrower segments contributes to better chip evacuation & surface finish, which increases accuracy & effectiveness in rough high speed machining.

Ceramics that cut fast

Milling difficult-to-cut high temperature superalloys (HTSA) by carbide tools necessitates low cutting speeds, normally 20-40 m/min (65-130 sfm). High speed machining with a small radial engagement, when the width of cut is up to 10% of a mill diameter, usually features cutting speeds of 70-80 m/min (230-265 sfm). The metalworking industry is always seeking ways to increase productivity when manufacturing parts from HTSA; & low cutting speed is one of the existing barriers to this goal. A solution may be found in applying cutting ceramics as a tool material for high speed machining. ISCAR has developed solid ceramic endmills that enable a dramatic increase in cutting speeds of up to 1000 m/min (3280 sfm) when compared to tools made from cemented carbide. The new endmills have a diameter range of 6-20 mm (0.236-0.787 in) & are designed with 3 or 7 flutes. Introducing the ceramic endmills in rough milling operations has proved to decrease machining time drastically & to enable fast preshaping of a part for further finish operations.

High speed master

Long-reach high speed milling operations require tools with long overall length. A solid tool concept is not an economically attractive option. An assembled cutter comprising a body carrying a carbide cutting head is a solution that makes economic sense. Such an approach is at the core of ISCAR MULTIMASTER - a family of tools with exchangeable heads. A rich variety of tool bodies, heads, extensions & reducers ensures various tool configurations & fundamentally reduces a need for special tools. An important advantage of the MULTI-MASTER line is it's no setup time principle, whereby replacing a worn head does not require additional tool measuring or appropriate CNC program adjustment - the insert can be replaced without withdrawing the tool from a machine spindle. High assembly rigidity, a balanced structure & high geometrical accuracy make MULTIMASTER suitable for HSM. A typical example of this application is finish milling 3D surfaces of parts produced from hard materials. ISCAR's "MM HBR" bulb-shape head (Fig. 3), featuring a 240°-spherical cutting edge, center cutting ability and strict ISO h7 grade tolerance limits for the head diameter, was developed for this type of operation.

Reliable toolholding

High speed machining is impossible to perform without the use of reliable, high-grade balanced and accurate tool holders. Thermal shrink chucks are one of the most popular types of tool holder. ISCAR's line of SHRINKIN chucks includes the X-STREAM family of thermal chucks, featuring coolant jet channels along the shank bore. The new design provides coolant flow directed to the tool's cutting edges. In the high speed milling of aerospace components (E.g. the aforementioned blisks), a well-directed coolant significantly enhances performance. For deep pockets and cavities, the new chucks with pin-pointed coolant flow have resulted in preventing re-cutting, thereby improving chip evacuation and increasing tool life.

A wet coolant may be a means for upgrading machine tools from low-velocity to high-speed.

SPINJET, a family of compact coolant-driven high speed spindles, is capable of maintaining rotational velocity up to 55000 rpm & facilitate high speed machining even on the low-speed machines that are still so common in the shopfloor.

Changing technologies require new machining concepts: more productive, more economical, more sustainable. High speed machining has already proved itself as a method that meets today's industrial needs. The progress in producing workpieces by non-machining processes brings in focus low-power high speed roughing. Accordingly, cutting tool manufacturers already feel the growing demands for appropriate products. It is a definite trend, which, no doubt, should be considered.

Source: ISCAR