NC verification and simulation software has been used by aerospace manufacturers for more than 20 years, yet some NC programmers do not take advantage of the benefits it can offer. Given the expense of each part machined, NC simulation is generally regarded as an important step in the machining process. Simulation checks each machining operation as it is programmed, or as a final check after the programming is finished and post-processed for the specific machine. It's typically a quality checking process that ensures the part is cut as expected from the generated NC programs, without the risk of a machine collision.

These are valuable uses that justify software cost, often many times over. However, some resourceful companies have discovered that simulation software can be used to benefit their shop in ways that others overlook, sometimes even in ways that were unintended by the software developer.

Evolving strategies and techniques

One of the easiest ways to get more from simulation software is to simply use it. Test new, unproven, machining strategies virtually as an analysis laboratory. Other than the time required to virtually create and test new methods, there is no physical cost. An NC programmer can try and fine-tune radical new ideas several times over. A few hours spent trying out different methods could potentially save many hours of machine time, reducing tool and machine wear, wasted materials, energy costs, and human fatigue.

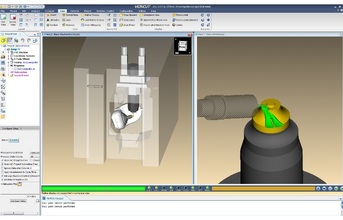

CAM vendors are developing new 5-axis strategies which are more complex; they are also developing new 5-axis roughing strategies that are improving the process of machining. New processes and new techniques must be employed and 5-axis machine simulation software that accurately represents each 5-axis machining cut in great detail will provide the necessary confidence to succeed. This also allows for new invention, experimentation and success with new techniques.

Removing the fear of multi-axis machining

CGTech, the developer of VERICUT software, has encouraged its customers to push the software to its limits. This can be well described using an example involving a creative NC programmer for a large aerospace engine manufacturer. Theywere looking for a faster way to make the leading edge of a titanium fan blade, and the NC programmer theorized that a new machining method could make the difference they needed.

Traditionally the process for making the part took many hours using a grinding technique. The NC programmer believed the part could be created using a 5-axis mill, but he knew he would need to convince his management before tying up the expensive machine for many hours cutting a test part. By using VERICUT to simulate the process, the programmer was able to create a video/review file to prove the process would work.

(Continued on next page)