Manufactured with CO2 compensation: The M4000 is the first Walter product to completely record and balance its CO2 footprint - from the delivery of the raw material, to when the finished product is shipped to the customer. The second step of the global system concept is CO2 compensation: As part of efforts to contribute to the reduction in greenhouse gases, Walter supports a climate-protection project on the island of Borneo in Indonesia. Tools that are manufactured with CO2 compensation carry a Walter seal: The Walter Green Flag.

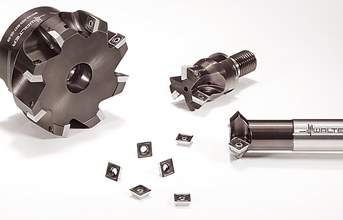

Wolfgang Vötsch, Senior Product Manager for Milling at Walter AG, explains why the M4000 range with system indexable inserts is the right product at the right time:

Increased cost-effectiveness and efficiency: One insert for several tools - since system tools can be used for a wide range of applications, this reduces storage and procurement costs for the user. In field tests, we were able to reduce cutting costs by half for each workpiece. The power requirement was also reduced by approximately 15 per cent.

Simple handling reduces complexity: With the M4000, we are introducing a new type of laser engraving - even on the smallest tool diameters, we can now include all the important information, such as details about the assembly parts and torque. New packaging makes it easier to retrieve tools.

Using resources sensibly and conserving them: For us and our customers, sustainability is an increasingly important competitive factor. Consumers want to know how something was manufactured. Added to this is the fact that many raw materials are becoming increasingly scarce and, as a result, increasingly expensive. The M4000 therefore involves an initial approach to recognising the CO2 footprint and to then being able to optimise it.

For more information: Walter Tools India Pvt. Ltd.; Phone: +91 20 30457300, Email: service.in@walter-tools.com; Website: www.walter-tools.com

END