Textile fabric as strain relief

The material enveloping the fibres largely determines whether a fibre optic cable can withstand movements. Aramide fibres, i.e. synthetic fibres that give bulletproof vests or fibrereinforced plastics their exceptional properties, are often used here. If the cable is stretched, the textile sheath absorbs the tensile force and prevents the fibre optic cable from also being stretched.

Each cable type undergoes rigorous testing at LAPP before being recommended for a particular application. In these tests, LAPP engineers test the torsion of cables for wind power plants in an old lift shaft by twisting the cables over a total length of 12 metres. This process is extraordinary in the cable industry. Other manufacturers test shorter cable lengths twisted at more acute angles and extrapolate this data to estimate the figures for longer cable lengths. LAPP just dosn't rely on what's written on paper but check every cable in realistic conditions.

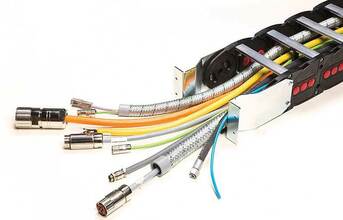

Everything from one supplier

Customers are increasingly requesting preassembled cables, i.e. cables with mounted connectors that are often already built into the energy chain. LAPP Systems, a subsidiary of the LAPP Group, has long provided these kinds of preassembled integrated systems. Customers like to be safe in the knowledge that all components are perfectly matched, particularly in flexible applications. Under the new name of ÖLFLEX® CONNECT, LAPP is now bundling all global preassembly activities for customers, including consultation. To this end, the company is expanding its corresponding production and

preassembly capacities in America, Europe and Asia. The customers thus benefit from customised solutions, high quality thanks to the optimum interaction of all components and expert on-site consultation.

Source: Lapp India

END