Does a cable break if it is bent or twisted too much? Not if you choose the right cable for the required application. This article explains where the challenges lie and the technical ideas that LAPP is using to overcome these issues as the leading supplier of connection solutions.

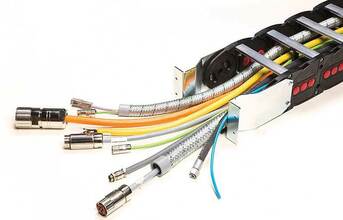

Cables have long been high-tech products. There is now a wide range of options when it comes to the material, processing methods and preassembly. This variety is necessary as the demands placed on cables, particularly regarding flexibility, have risen sharply over the last few years. One of the most gruelling places to install a cable is in a power chain. Here servo cables such as the ÖLFLEX® SERVO FD 796 CP and the ETHERLINE® or HITRONIC® fibre optical data cables are placed very close to one another. They move to and fro during a machine's power cycle, sometimes faster than 5 m/s with accelerations over 50 m/s2. In highly dynamic applications, several things must be borne in mind in order to accommodate the demand for increased service life while guaranteeing lower space requirements, reduced weight and a small minimum bending radius.

Three types of movement

There are three different types of movement in cables:

• Torsion: the cable is twisted about a longitudinal axis. Pure torsional movements are found in wind turbines where the cables run from the rotating nacelle down to the tower;

• Drag chain: the cable is bent, sometimes millions of times, in the drag chain;

• Winding and unwinding: this is where cables are unreeled from drums, for instance in stage applications or on live TV, then reeled back onto them and stored after the event.

(Contiuned on next page)