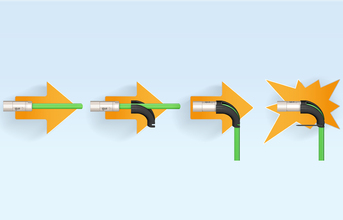

The motion plastics specialist igus has developed the ibow for a quick and easy angling of plug connectors. The angle adapter can be installed either during assembly or retrospectively on existing cables. To ensure operational reliability, the connector need not be removed from the cable. The ibow reduces your planning and delivery times as much as the assembly and storage costs.

Slide it on, bend the cable, fix and ready to use! In just a few steps, the new igus ibow, from the motion plastics specialist igus, can be used to attach cables with an angled plug connection and save space. With this simple injection moulded part, igus allows flexible connection of cables to a machine, whereby the angle of connection is freely selectable. "With the use of the igus ibow, cables can be connected just as easily to machines as without the adapter," explains Christian Stremlau, head of the readychain/readycable division at igus. "Customers do not need specially trained personnel and also save twice because they only need to get one type of plug connector, the straight connectors and their harnessing are also significantly cheaper than angled connectors." Users can therefore obtain the identical connector types as harnessed readycables from igus and also choose the best angle for connecting to the machine later. This saves process and storage costs and above all eliminates errors.

By using the cost-effective igus ibow, the connector does not have to be removed from the cable, which saves time and is also safer. As soon as the cable complete with connector has been pushed through the adapter and angled, it must be fixed with a cable tiewrap. In this way, it can also be removed again easily later if required. Depending on the customer's requirements, igus supplies the ibow as an individual part in various installation sizes or already harnessed together with the appropriate cables. Users can also specify the desired colour or add additional individual labels.

END