During the chemical reaction, hydrogen molecules are separated into electrons and hydrogen ions at the hydrogen anode, where the platinum catalyst strips away the electrons from the hydrogen molecule. The electrons travel to the oxygen cathode, generating electricity to power the motor.

Meanwhile, the hydrogen ions cross a polymer membrane to reach the oxygen cathode, where water is produced as a byproduct of hydrogen ions and electrons being exposed to airborne oxygen. Platinum also functions as the catalyst for this reaction.

Platinum is essential for electricity generation in fuel cells, playing a vital role in increasing fuel cell electricity generation efficiency.

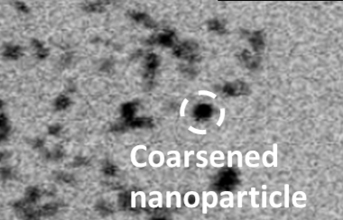

However, platinum is scarce and costly. Furthermore, as electricity is generated, platinum nanoparticles coarsen, thereby decreasing fuel cell output. In order to prevent coarsening and maintain catalytic performance, the behavior underlying the coarsening process must be identified. However, the minute scale of the platinum nanoparticles renders observation via conventional means difficult.

Features of the newly developed observation technique

The conventional method of platinum nanoparticle observation is a fixed-point comparison of pre-reaction platinum particles with post-reaction particles.

Through this method, it was discovered that post-reaction platinum nanoparticles are coarser with reduced reactivity. But, the causes of this reduction can only be hypothesized due to the inability to observe the behavioral processes leading up to the coarsening.

In contrast, the new observation technique involves a new scaled-down observable sample that can simulate the exact environment and conditions occurring in fuel cells. This, in addition to a newly developed method of applying voltage to samples mounted inside a transmission electron microscope, allows the coarsening process to be observed in real-time at all stages as electricity is generated.

A transmission electron microscope is a microscope capable of observation and analysis of atomic-sized (0.1 nm) materials.

End