Toyota Motor Corporation and Japan Fine Ceramics Center (JFCC) have developed a new observation technique that allows researchers to monitor the behavior of nanometer-sized particles of platinum during chemical reactions in fuel cells, so that the processes leading to reduced catalytic reactivity can be observed.

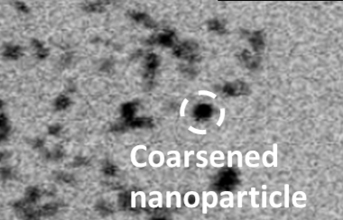

Platinum is an essential catalyst for the electricity-producing chemical reactions occurring between oxygen and hydrogen in fuel cell stacks. Reduced reactivity is the result of "coarsening" of platinum nanoparticles—a process whereby the nanoparticles increase in size and decrease in surface area. Up until now, however, it has not been possible to observe the processes leading to coarsening, making it difficult to analyze the root causes.

The new observation method can enable discovery of the points on the carbon carrier where platinum coarsens, as well as level of voltage output during the coarsening process.

The method can also help determine the different characteristics of various types of carrier materials. This all-aspect analysis can provide direction to R&D focused on improving the performance and durability of the platinum catalyst, and of the fuel cell stack.

Background of research activities

Fuel cells generate electricity through the chemical reaction of onboard hydrogen gas with airborne oxygen. More specifically, each individual cell generates electricity through the chemical reaction between each oxygen cathode and hydrogen anode, with water produced as a byproduct.

Continued to next page