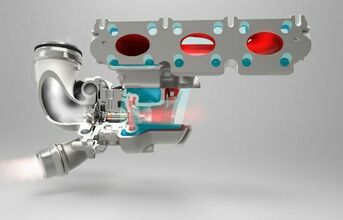

Continental's powertrain developers have launched series production of the first car turbocharger with an aluminium turbine housing. Integration of the unit in the three-cylinder gasoline engine for the MINI Hatch has been ongoing since spring 2014.

"Aluminium in a turbocharger designed for cars is a real milestone," says Wolfgang Breuer, Head of the Engine Systems Business Unit of the Powertrain Division. "With this lightweight material, we are saving nearly 30% of weight compared to a conventional turbocharger while simultaneously reducing costs and achieving system benefits."

Continental's innovative turbocharger with aluminium turbine housing is making its debut in a demanding downsizing application: a turbocharged three-cylinder engine with 1.5l of cubic capacity and 100kW of power.

"It's not just the aluminium that makes the turbocharger special; it was also developed from being a typical add-on component to an integral part of the engine," explains Udo Schwerdel, Head of the Turbocharger Product Line, Engine Systems, Powertrain Division. "In order to meet the requirements placed on the unit and its integration in the cylinder head, we worked closely with the BMW Group starting from the simulation phase - an indication of trust that we greatly appreciate."