Vertical turning solutions are machines that offer a range of capabilities for machining large and complex parts. The vertical design provides better support and stability for the work piece, resulting in more precise and accurate parts. With heavy-duty construction and multiple tooling options, vertical turning solutions are used in a wide range of industries, including aerospace, energy, and transportation.

Precision and accuracy

WIDMA's Vertical Turning Lathes (VTLs) fit the needs of manufacturers looking for high accuracies at high speeds. VTLs are ideal for machining components of massive size and complex geometries such as pumps and valves, railway wheels, bearings, and graphite blocks with accuracy. The company stated that several customers have benefited from upgrading their conventional set-ups to their machines, as it leads to productivity boost and quality improvement due to reduced cycle times and improved accuracies.

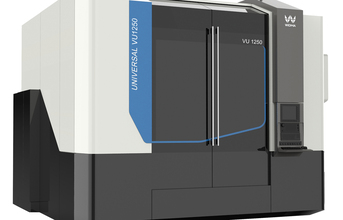

Ranging from simple turning to complex 5-face machining, these machines are classified under three categories- Multi-Tasking Turn Mill Machines (VU), Vertical Turn Mill Machines (VM), and Vertical Turning Machines (VT) - from two-axes to five-axes configurations with table sizes ranging from 500 mm to 3000 mm.

The VU-5 Axis Multi-Tasking Turn Mill Machine is an industry leading offering from WIDMA that offers high accuracy, precision, and versatility. With the ability to perform multiple machining operations on a single work piece, they reduce setup time, improve accuracy, enhance productivity, and offer cost-effective solutions, finding applications in several industries.

Key Features:

- 5-Axis Machining Capability: to perform complex machining operations with high accuracy and precision.

- Dual Spindles: to perform simultaneous machining operations on both ends of the work piece.

- Automatic Tool Changer: which quickly changes the cutting tools to perform different machining operations.

- High-Speed Machining: to reduce machining time and improve productivity.