Reducing the complexity of automation solutions while saving money, time and installation space is a declared goal of engineers all over the world. This applies to cable planning as well. Here, so-called hybrid technology has become one of the major trends in recent years. While servo drive systems used to require several cables to transmit energy and data, hybrid cables simply combine the cores. "Hybrid technology is a pioneering development that we, as a cable specialist, are 100 per cent convinced is the way to go," says Markus Hüffel, Product Manager readychain and readycable at igus. "We are therefore continuously expanding our portfolio of ready-to-connect hybrid cables from the readycable series in order to offer our customers a fast, reliable, cost-effective solution for continuous use in energy chains."

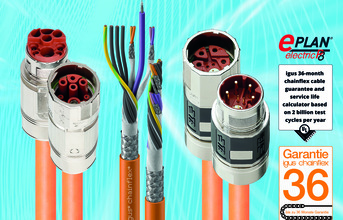

The latest addition to the readycable series includes two models: a hybrid cable for motors from SEW-EURODRIVE, a German manufacturer, with the MOVILINK DDI interface, and a hybrid cable for Siemens servo drives suitable for SINAMICS S210. In addition to PUR, the outer jacket can be made of lower-cost polyvinyl chloride (PVC). "Lean industrial processes in harnessing, very short throughput times and a high degree of warehousing enable designers to quickly have the new hybrid cables delivered directly from stock - at the desired length to the centimetre, without cutting charge, ready to connect and fit for immediate use," says Hüffel. To save even more project planning time, igus also provides direct links to the macros for the EPLAN Electric P8 planning software on their website. This allows the cables to be dragged and dropped into the digital cable plan as building blocks, reducing cable planning time by up to 50 per cent.

Like all cables in the readycable series, the new hybrid cables have a strong outer jacket, a strain-relieved core, movement-optimised stranded wires, a stranded structure with a short pitch length and a gusset-filling extruded inner jacket. "This design and these high-quality materials make our new hybrid cables fail-safe in continuous use in energy chains, even in compact applications," says Hüffel. Materials with good electromagnetic compatibility prevent the energy and data transmission cores from having a negative influence on each other. All models have undergone several million test cycles in the 3,800 square meter igus test laboratory. Igus, therefore, offers an above-average chainflex cable guarantee of 36 months. They also provide an online tool, with which customers can calculate the expected service life of their specific application.