With a wide range of lightweight initiatives with chuck jaws,

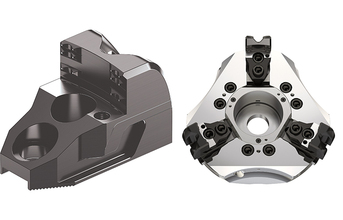

SCHUNK is breathing new life into turning applications. The competence leader for gripping systems and clamping technology is now offering a range of diverse claw and stepped jaw models

for raw part clamping from the world's largest range of standard chuck jaws also optionally as a lightweight version. Depending on the jaw type, one saves around 40 percent of the weight but completely retain all of the characteristics of the standard jaws, such as stability.

The lightweight chuck jaws primarily reduce the effects of centrifugal force at high speeds, which reduces the loss of clamping force and increases process reliability. Alternatively, parts that are sensitive to deformation require lower clamping forces in order to machine workpieces in a process-stable way.

Other advantages are improvements to the interfering contour as well as energy saving since less mass is accelerated and slowed down.

The weight-reduced chuck jaws therefore provide the ideal preconditions for the use on lightweight lathe chucks such as the SCHUNK ROTA NCE, but also on conventional lathe chucks with fine serration or tongue and groove.

END