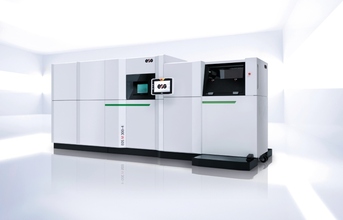

A new level of repeatable part quality

The new platform meets the most demanding requirements of today's and future production environments in terms of efficiency and scalability. At the same time the system design also enhances part reliability and quality. The robust casted frame enables 24/7 process capabilities. A permanent filter system has been integrated to eliminate the need to open the system up periodically for filter changes. The new, lifetime recirculating filter system offers automated cleaning, with residue collected in a bin beneath the build chamber. Longer jobs can be processed without job interruption.

At the same time, the system line offers automatic job start procedures. Depending on the needs of the user, the system line also includes powder contact-free solutions for demanding health and safety standards. Like for all other systems, EOS offers fully integrated remote service and consulting for the EOS M 300 series to - for a sustainable business.

A system line for the most demanding customer requirements

Dr. Tobias Abeln, Chief Technical Officer (CTO) emphasizes: "With its modular set-up and its scalable and flexible concept, the new system line clearly focuses on the high customer demands for AM production. It sets a clear focus on productivity, and lowest costs-per-part and was developed for automation and (software) integration in current and future factories." He goes on to say: "The EOS M 300 series is the only 3D printing solution for digital industrial production and specifically meets the demanding requirements in a production environment. It offers industrial-grade and integrated data, powder and part flow and can be easily incorporated into production facilities. We bring this technology into smart factories."

(Continued on next page)