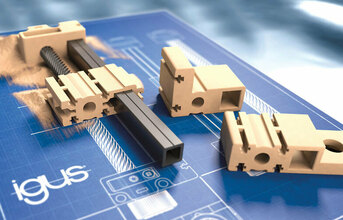

The motion plastics specialist igus takes a completely new approach to drive technology: the SLTI3 lead screw unit offers customers

the highest degree of variability in the design of their individual linear axis. Made possible by 3D printed carriage and shaft end supports. This means that lubricantfree and maintenance-free lead screw units can be implemented cost-effectively and very quickly according to customer requirements.

Lubrication-free and maintenance-free linear axes from igus are already the core components of many moving applications, both in the automotive and in the packaging machine. Among them is the low-profile drylin SLT series, which has a drive system with ball-bearing, laterally arranged lead screws with trapezoidal or high helix thread and is suitable for both motor and manual operation. The drylin SLTI3 lead screw unit now supplements this type series with a very flexible system. For this purpose the number of components has been significantly reduced so that the lead screw unit can be assembled in seconds. Customer-specific stroke lengths are also possible, as is the use of trapezoidal or high helix threads according to requirements. Entirely new degrees of freedom in design are promised by the first complete linear carriage from the 3D printer as well as printed shaft end supports, which are manufactured in the laser sintering process.

(Continued on next page)