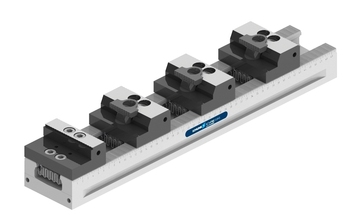

The SCHUNK multi clamping vise KONTEC KSM2 is a reliable and precise all-rounder for stationary workpiece clamping. In order to efficiently use 3, 4, or 5 axis machines, it can clamp several parts at the same time which are located next to each other.

Slim jaws without protruding, interfering contours thereby allow a particularly high part density, and an optimum accessibility. Its performance during large workpieces clamping together with other KSM2 multi clamping vises is convincing. A hardened and ground fine serration provides for maximum robustness, precision, and dimensional stability.

A system, based on wedge clamping elements ensures that the workpiece is pulled down during the clamping process, no matter how big the workpiece is, and even in case of high feed rates, a safe and precise machining is ensured. One single actuation key is sufficient setting up the vise's actuation for clamping the workpieces, to completely remove the chuck jaws per quick-change, or to convert the clamping system quickly and flexibly onto another workpiece.

The latter has also been facilitated with the lasered scale. Equipped with adapter plates and standardized interfaces, the KONTEC KSM2 seamlessly fits into the world's largest modular system for stationary workpiece clamping from SCHUNK. If combined with the SCHUNK quick-change pallet system VERO-S NSE plus 138, any gauges for bore holes can be adjusted within a grid of 2 mm along the multi clamping vise within seconds.

For machining dynamically balanced parts however, the multi clamping vise can be equipped with a manual ROTA-S plus 2.0 lathe chuck from SCHUNK. The KONTEC KSM2 is available in five or four lengths between 260 and 650 mm at jaw widths of 65 or 90 mm. It achieves clamping forces up to 25 kN, and can be combined with a wide range of chuck jaws for the first and second set-up.

Contact: Satish Sadasivan, Schunk Intec India, Ph.: 080-40538999; Fax: 080-40538998; Email: info@in.schunk.com; Web: www.in.schunk.com