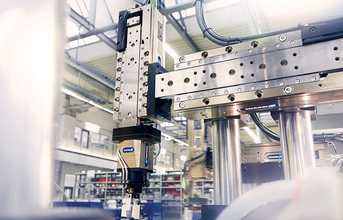

Insiders are speaking of a revolution, pragmatics of an intriguing simplification. Whatever your take on it, you can't deny that the linear modules in the SCHUNK ELP series define a new era of mechatronization in high-performance assembly. For the first time ever, SCHUNK, the competence leader for clamping technology and gripping systems has managed to develop an ultra-compact linear module with a low-maintenance 24V linear motor drive where commissioning it is as easy as making yourself a cup of coffee. Within SCHUNK's mechatronic modular system, the series top off the segment of easyto-use mechatronic alternatives. Entire pick & place and feeding tasks can now be solved just as easily electrically as it has been with pneumatic modules.

The drive, controller, and unique autoteach technologies are completely integrated into the compact module. To commission it, all you have to do is connect the axis using standard plugs (M8/M12), and set the end position mechanically using an Allen key. The speed of retraction and extension can be regulated according to the add-on weight by means of two rotating switches. You therefore do not need to possess mechatronic know-how or space in your control cabinet to use the linear module. An integrated LED display in the axis indicates the status of the teaching process. Between two and five strokes are normally all it takes before automatic programming is complete. The process is then constantly monitored and flexibly adapted to any changes.

(Continued on next page)