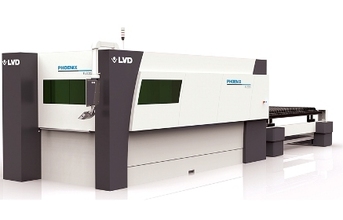

The Phoenix FL completes LVD's fiber laser line-up. The new fiber laser system unites cost efficient and dynamic laser cutting together with LVD's laser automation possibilities.

Quality comes first: The Phoenix offers the perfect balance between performance and price. The compact, modern machine design includes a welded steel frame construction that minimizes deformation caused by high acceleration thus improving overall machine accuracy.

Powered by a high efficiency solid-state doped fiber laser source, the fiber laser provides fast, accurate processing of various sheet thicknesses and types. The Phoenix FL features a lightweight, high rigidity beam delivery system to allow for highly dynamic processing.

The Phoenix maximizes uptime with an integrated automatic shuttle table system that allows one table to be loaded while the machine is cutting on the other table. Table change time is only 30 seconds.

Touch screen control & interface: LVD's touch screen control and user interface, TOUCH-L, make the Phoenix easy to use and operate. TOUCH-L employs a 19" touch screen and icon driven user interface to efficiently and effortlessly guide the user through all necessary man-machine interactions.

TOUCH-L also incorporates a part programming and nesting feature allowing users to import drawings directly into the control, applying cutting technology and nesting sheets at the machine.

Efficient operation: The Phoenix FL features the latest in fiber laser source technology with a wall plug efficiency of up to 30%. The maintenance-free fiber laser resonator utilizes the latest fiber laser technology for reliable trouble-free performance.

Advanced automation options: Modular automation options further increase the productivity and throughput of the Phoenix FL. The laser cutting system is offered with the option of a Compact Tower (CT-L) and the Flexible Automation for Lasers (FA-L) developed by LVD.

CT-L is a compact material warehousing tower with an integrated load / unload system and a shelving unit for storage of raw material and finished parts. FA-L is a system for interchanging finished and unfinished sheets on the table within 40 seconds and includes thickness control and automatic sheet separators.

For more info, contact: Product Manager Laser, Kurt Van Collie, LVD Company nv; Tel: +32 56 43 05 11; Email: kvcl@lvd.be; Website: www.lvdgroup.com