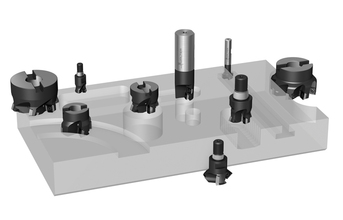

The universal M4000 milling system from Walter previously consisted of the M4002 high-feed cutter, the M4132 shoulder milling cutter and the M4574 chamfer cutter. The system is now being extended with the addition of the M4575 T-slot cutter and the M4792 slot drill.

As a result, users of this tool range can now successfully tackle just about all milling operations in many sectors of the metal cutting industry, using one and the same system. And that's not all. All the milling cutters are also equipped with the same system insert, which is square, positive and has four cutting edges. One indexable insert for all milling cutters, and one milling cutter range for almost all operations.

For machinists who are cost-conscious when making their calculations and whose work involves applications that are frequently changing, this universality of tool use is a major factor in achieving higher profitability. "In field trials using the M4000 milling cutters, we were able to reduce cutting tool material costs per component by a half," explains Wolfgang Vötsch, Senior Product Manager for Milling at Walter AG in Tübingen.

"In addition, because the range of equipment in the tool cabinet is also considerably reduced, this also means a drop in costs relating to procurement and stock maintenance."

(Continued on the next page)