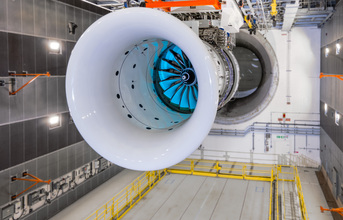

Rolls-Royce has announced the successful completion of the first tests of its UltraFan technology demonstrator at its facility in Derby, UK. The tests took place in the world's largest and smartest indoor aero-engine testing facility - Testbed 80 and were conducted using 100 per cent Sustainable Aviation Fuel (SAF), derived primarily from waste-based sustainable feedstocks such as used cooking oils, was provided by Air bp.

This marks the first time in 54 years when the aero-engine manufacturer has tested a brand-new engine architecture. UltraFan delivers a 10 per cent efficiency improvement over the Trent XWB, which is the world's most efficient large aero engine in service.

In the nearer term, there are options to transfer technologies from the UltraFan development programme to current Trent engines, providing customers with greater availability, reliability and efficiency. In the longer term, UltraFan's scalable technology from ~25,000-110,000lb thrust offers the potential to power new narrowbody and widebody aircraft anticipated in the 2030s.

Tufan Erginbilgic, CEO, Rolls-Royce plc, said: "The UltraFan demonstrator is a game changer - the technologies we are testing as part of this programme have the capability to improve the engines of today as well as the engines of tomorrow. When combined with Sustainable Aviation Fuels, more efficient gas turbine engines will be key to hitting the industry's target of Net Zero flight by 2050."

Testing the demonstrator is the culmination of many years work, which has been supported by the UK Government through the Aerospace Technology Institute (ATI), Innovate UK; the EU's Clean Sky programmes plus LuFo and the State of Brandenburg in Germany.

UK Business and Trade Secretary, Kemi Badenoch, said: "This cutting-edge technology will help the transition towards a greener future for aviation while attracting further investment into the UK's aerospace industry, helping grow the economy. We will continue to work with manufacturers like Rolls-Royce as we seek to grow the UK's share of the global aerospace market."

UltraFan is a completely new design compared to the around 4,200 Rolls-Royce Civil large engines currently being used. It incorporates a geared design that no other company has done on this scale before. This also means that them in a position to offer a portfolio of two-shaft, three-shaft, direct drive and geared propulsion solutions to power future aircraft.

Key engineering features of the demonstrator include:

- A new, proven, Advance3 core architecture, combined with our ALECSys lean burn combustion system, to deliver maximum fuel burn efficiency and low emissions

- Carbon titanium fan blades and a composite casing

- A geared design that delivers efficient power for the high-thrust, high bypass ratio engines of the future. The power gearbox has run at 64MW, an aerospace record