At the turn of the century, ISCAR introduced a groundbreaking design concept: assembled drills with exchangeable solid carbide cutting heads. This innovation significantly transformed the company's holemaking product programme. The concept involves mounting a precise carbide head into a steel holder using a "self-clamping" principle, which relies on the holder's elastic deformation, eliminating the need for mechanical clamping mechanisms. This approach is characteristic of various successful ISCAR products, such as the SELF-GRIP and MULTI-MASTER tool lines, which have not only substantially improved machining performance but also revolutionised traditional perspectives on cutting tool design.

In these assembled drills, the cutting head features a specially shaped rake surface to optimise chip formation, a centering area to ensure high accuracy, and stoppers and locking sections for reliable security. The holder—the drill body—is produced from high-strength steel and boasts an innovative design, including the head pocket, helical flutes, and internal channels for coolant supply. Advancements in technology, particularly in powder metallurgy processes and CNC machining, have made this design feasible.

The concept of assembled drills with carbide heads offers several key advantages:

1. Due to its rigid structure, reliable clamping principle, unique cutting geometry, and advanced carbide grade of the heads, the drills guarantee productive results. This significantly reduces cycle times and enables high-quality holes. These drills can be used for machining a wide range of materials including steel, stainless steel, cast iron, titanium, and high temperature alloys.

2. High repeatability and ISCAR's "no-setup-time" principle promise that a worn head can be replaced without removing the drill from a machine, eliminating additional setup operations, and considerably decreasing downtime. The simple change of the heads makes the drills easy to handle and user friendly.

3. The drills are available in a wide range of diameters and overall lengths to suit various applications.

4. The use of interchangeable heads diminishes the need for a large drill inventory.

Over the past 20 years, ISCAR's drills with exchangeable carbide heads have undergone significant evolution. Beginning with the CHAMDRILL family, each new phase in the concept's enhancement has led to products that outperform their predecessors. Today, SUMOCHAM is ISCAR's most popular family of assembled drills with exchangeable carbide heads and is highly regarded by customers. The continuous pursuit of increased drilling productivity, particularly when machining materials that produce fine chips, has resulted in the creation of LOGIQ-3-CHAM—a family of three-flute drills that utilise the same self-clamping approach.

ISCAR's development of carbide-headed drills continues to aspire. Unsurprisingly, ISCAR's latest product campaign, LOGIQUICK, has unveiled innovative designs that not only enrich existing product families and broaden their scope but also pave the way for new areas of application.

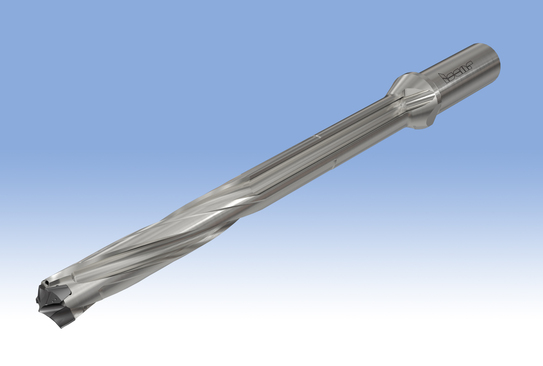

The new holder with three-flute heads allows a 10:1 drilling depth-to-diameter ratio. The holder's main feature is a specific flute design that minimally affects the tool's structural strength.

Another innovation is the expansion of the LOGIQ-3-CHAM family's application to include counterboring. The specially designed three-flute heads are mounted on existing tools, transforming them into highly efficient counterbores. The unique design features of the heads—including a corner chamfer for rapid chipping, specialised deflectors for improved chip formation, and a unique margin for enhanced support and guidance—significantly boost performance when machining materials like sticky steel, stainless steel, and high-temperature superalloys (HTSA). This design facilitates a broad spectrum of counterboring operations, ensuring high-quality holes, even when machining cross-holes with inclined surfaces.

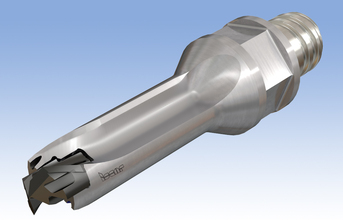

The CHAM-SPADE-IQ is a new family of holemaking tools with exchangeable heads. Introduced as part of the LOGIQUICK campaign, this family provides a solution for drilling steel profile construction beams. Machining beams often occur under non-rigid technological conditions, presenting a significant challenge for manufacturers. To address this issue, it is crucial that drilling tools have adaptive cutting geometry to compensate for the lack of rigidity. The newly introduced family, specifically dedicated to profile construction, includes two-flute carbide drilling heads and reinforced steel holders. The heads feature a specific self-centering cutting edge for secure hole penetration and sharp corners to prevent deformation. The durable structure of the holders maximises the dynamic stability of the tools when drilling at a depth-to-diameter ratio of up to 5.

New drills with MULTI-MASTER adaptations that carry exchangeable carbide heads essentially serve as a "bridge," connecting the successful SUMOCHAM and MULTI-MASTER families. These drills are components of a versatile modular tool assembly, allowing the mounting of drilling heads on a wide range of MULTI-MASTER tools. This facilitates not only easy and quick changes of the heads but also of the drill bodies. Moreover, the modular concept provides straightforward customisation and flexibility regarding overall length, diameter, and finding the optimal tool configuration.

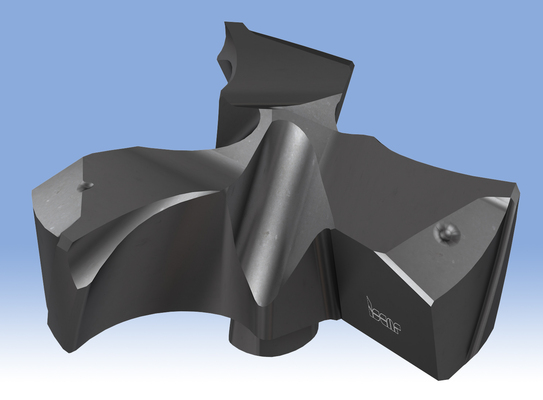

It's worth noting that the holemaking innovations in the LOGIQUICK campaign are not solely represented by assembled tools with exchangeable heads. Several products of another design concept can also be highlighted. One such product is the three-flute flat-bottom solid carbide drill with internal coolant channels. The drill features a small isle for improved penetration, wavy cutting edges for assured chip control, an optimised core diameter to increase tool rigidity, and narrow wiper sections to reduce friction for a surface finish in combination with internal coolant supply that extends tool life and improves chip evacuation. These attributes contribute to the promising prospects of this product line.

In the boring line, a new series of boring heads with extra-fine digital adjustment has replaced the existing heads with an MB connection. In the milling line, the portfolio has been enhanced with the addition of the QUICK-D-MILL—a family of multifunctional indexable cutters. These versatile "all-in-one" cutters are suitable for a wide range of machining applications, including milling of shoulders, slots, pockets, as well as drilling flat-bottom holes.

The overview of the mentioned products highlights that ISCAR's focus on holemaking continues to drive their development efforts. With the metalworking industry seeking solutions to enhance holemaking performance, ISCAR is confident that their latest LOGIQUICK drilling developments will effectively meet the industry's demands.