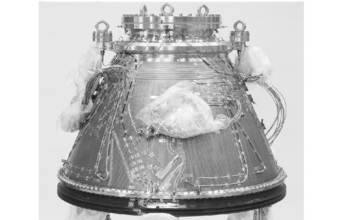

The ETID Nozzle Extension builds on GKN Aerospace's patented manufacturing method for actively cooled nozzle extensions, i.e. the so-called "Sandwich" laser welded channel wall technology. The sandwich has a reinforcement jacket using additive manufacturing in the form of laser wire deposition. ETID is part of the ESA funded Future Launcher Preparatory Programme guiding Europe's next-generation upper-stage rocket engine design.

These technologies have matured over almost two decades of continuous improvement in GKN Aerospace's center of excellence in Trollhättan Sweden and it shows clear customer benefit in liquid rocket propulsion applications. Some key operations of the manufacturing of the ETID Nozzle have been performed and developed in close cooperation with Force Technology in Denmark.

The program is currently hot-fire testing at DLR's P3.2 test facility in close collaboration with ArianeGroup, Ottobrunn. The test campaign has completed the run-in tests and the first test block with excellent results. The second block with additional technologies and with extended duration of the tests has also been successfully completed. After completion of the third test phase the ETID NE technology is ready to target future upper stage flight applications.

(Continued on next page)