Two new regulations aimed at imparting greater safety and comfort for bus passengers came into effect from April 1, 2015 in India. These are the Bus Body Code and the mandate to make ABS standard for commercial vehicles.

So where do these buses - Deccan and Corona - stand on these two regulations? Prasad is quick to answer: "In fact, our buses are homologated based on these codes. We have already received the certificate for the 12m bus. The 14m and the 8m bus certificates are awaited and will, fully confirm to the new code."

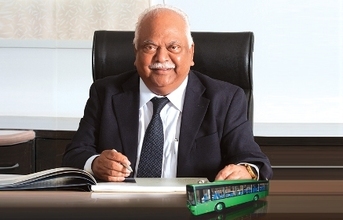

M Balaji Rao, Director & Principal Advisor for Corona Bus and Deccan Auto, now joins the conversation to share more technical information on the new buses. The Corona brand of buses for the city operations - Balaji points out - are based on the monocoque design. These are the only buses in the Indian market with a monocoque design, he claims.

"These buses have independent front axle just as in a car. The ride comfort due to these two reasons is unbeatable. The monocoque also helps in the reduction of the weight and hence adds to the fuel efficiency. The safety of the passengers is enhanced due to the transmission of the forces in case of an accident across the bus structure and the shock absorption is far superior to the other designs. The Corona City buses also offer an end to end single floor plate unlike the other similar buses with steps at the rear portion."

The Deccan brand of buses will compete in the premium luxury segment and will have toilets, individual audio/video consoles, pantry and covered hack tracks. "These buses will come in 330 and 375 Hp engines. We also give a combination of 2x2 and 2x1 seating to enhance the earning with a business class luxury for the business traveller. We would want the companies to move from air travel to bus travel with these conveniences," Balaji shares.

While the Hyderabad plant's current capacity is 3000 units per year, this year the plant has an order book of 320 buses in hand. Deccan Auto plans to take the order book to 1000 by the end of this year. It also plans to export buses to Africa where the Group has presence in more than a dozen countries having 12 operational cement plants and six more are in construction.

So it makes sense. "We are looking at doubling our production capability in the next six years. The requirement of buses for India is going to increase dramatically if the smart city concept is put in place. We don't see a reason on why we should not be looking at a volume of 6,000 buses by the end of the 8th year," Balaji adds.

Prasad also wants to ensure that the buses coming out of Deccan Auto's Hyderabad manufacturing plant are truly ‘Indian' in the making. For example, 95 percent of the components of Corona are Indian. "The engines are from Cummins, the axles from Meritor, the A/C is based on the customer choice while most other components are all Indian. The Auto transmission is the only major item imported as of now from Allison USA," Balaji shares.

Coming to the Deccan brand, all the components of the bus body are from Indian vendors while the chassis and the power train are imported as of now. "The Engine and Gear box is from WeChai and they are putting up a plant in Pune for engine manufacturing. WeChai also makes axles and various other under chassis components. In the next few years we would be able to get all these components from them in India, if our volumes grow the way we have planned. We will make sure that the import content is drastically reduced," Balaji says.

(Continued on the next page)