At the Cusp of a Societal Shift

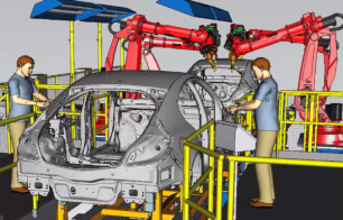

Robots and automation are invigorating once-sleepy Indian factories, boosting productivity by carrying out low-skill tasks more efficiently. Industrie 4.0 - the vision for the future of manufacturing that is becoming an increasingly stronger theme in global manufacturing - links the real-life factory with virtual reality.

Robots are currently assigned multiple and dynamic tasks by human operators, however the robots of tomorrow will be able to solve problems together. Robots will have the ability to interact with each other, share information about pending operations, and assign tasks together. Nevertheless, robots have to be linked to a flexible conveyor and automation system to improve product quality, lower costs, and increase efficiency.

The key for a successful industrial production under an Industrie 4.0 environment is strong product customisation under flexible production conditions. This will ensure reduced error margins thanks to the availability of real-time data throughout the production cycle.

Growing technological advancements and rapidly decreasing costs are leading to a vast increase in the number of jobs which robots can perform in an efficient manner. This will lead to a major increase in productivity, and also to the replacement of human workers in many sectors of the economy. The growing use of robots will reduce the competitive advantage which cheap labour historically provided by many developing countries.

The combined impact of all these technological advancements and industry trends puts a sharp focus on super shopfloors to transform the future of workplace efficiency, improve profit margins for companies and enhance the quality of life of the end users. How Indian manufacturers employ this evolving technology to realise its full potential, will determine the future of shop-floors and consumers alike.

END

The author is Marketing Manager, Asia Pacific, Siemens PLM Software